When it comes to smooth industrial operations, precision gears play a crucial role. These tools have the capacity to control the motion of the machine and manage the amount of force the machine should apply or tolerate. Thus, it becomes vital to choose the right type of precision gear for your settings. The correct kind can have a great impact on your machines. They reduce the chance of any type of breakdown and also assist in extending the life of your machines. In this blog, we will try to cover all aspects of precision gears and how you should choose the right one for your business from a trusted precision gear manufacturing company.

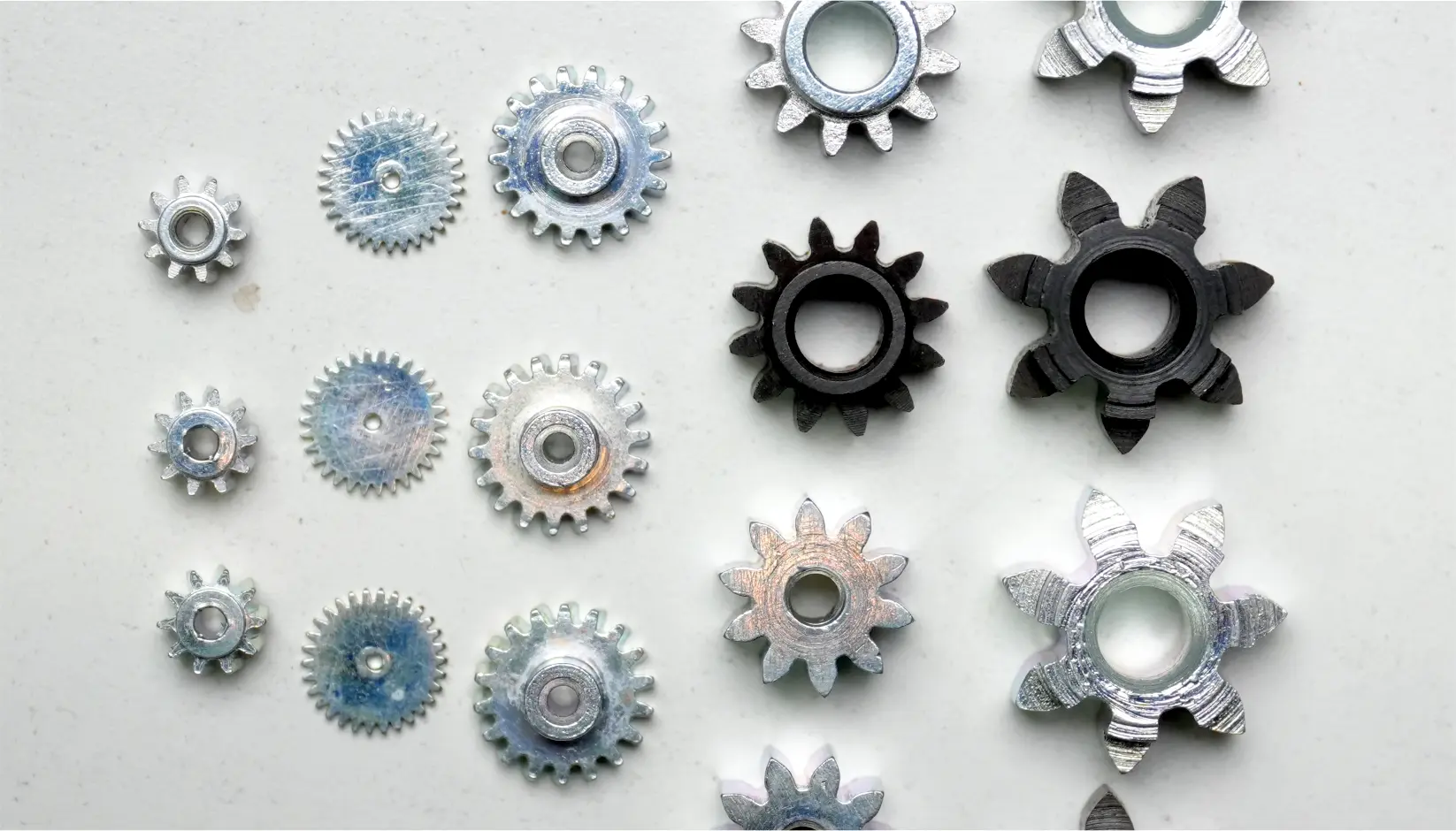

A precision gear is a gear that is manufactured at extremely high accuracy and tight tolerances. They are also known as accurate gears. These characteristics assist in enhancing efficient and precise passage of movement as well as energy in mechanical systems. As opposed to regular gears, precision gears are designed to minimise any inaccuracies like backlash, vibration and unbalanced torque; this is why they are required in such applications where precise positioning is required and predictable performance is demanded.

Precision gears are highly significant in modern machinery, as they assist in the proper and effective flow of motion and power. They are used by many precision gear owners. They also have tight tolerances and accurate tooth profiles, unlike conventional gears. This in turn reduces backlash, vibration, and non-uniform torque. This accuracy is extremely useful in systems that need precise positioning and smoothness, like robotics, CNC machines, aerospace systems and medical devices. Precision gears are beneficial not only in creating reliability and maximum lifespan of devices but also general efficiency and safety of the system by ensuring stable functionality in the harsh environment.

The content of a precision gear directly influences its strength, durability, and efficiency of performance. The incorrect selection of material may result in premature failure, undue noise, or loss of energy, particularly where the demand is high. Each material has its own benefits that would work with the certain needs in the operations:

Powerful, resistant and able to support heavy loads and working round the clock. It is perfect in both industrial machinery and heavy usage applications where long-term functionality is needed.

It is not as strong as steel but is quieter in operation and has greater wear resistance. They tend to be used in precision tools and noisy environments where a smooth and silent motion is required and thus are preferred by many precision gear owners.

It is portable and rust-free and, therefore, applicable in moderate loads, but it is not as hard and wear-resistant as steel, so it is not ideal to use for heavy duty.

Looking for leading precision gear manufacturers in India for your next purchase of bulk precision gears? Swadeshi Gears has got you covered.

To choose the appropriate precision gear, it does not only depend on material but also on making certain that the gear fits the system or the machine it works in perfectly. It may cause vibration, noise or inefficiency or premature failure, with a well-matched gear improving performance, reliability and saving energy.

The following are the main factors to be considered:

The equipment should be in a position to take the peak torque and load of the system. Steel or alloy gears are preferred to be used in heavy machinery, whereas plastic or aluminium gears are used in light-duty machinery.

Gears with high precision and low backlash are always used with machines needing high accuracy in movement, such as robots, CNC machines or medical equipment.

Certain conditions such as temperature, humidity, dust or chemical contacts in the industrial environments should also be put into consideration during acquisition of the appropriate precision gears in your business. Plastic gears are used in such situations.

In such areas as a laboratory or an office, quiet work is a necessity. Therefore, plastic gears are preferred in such environmental conditions.

Select the corresponding gear with the level of your maintenance. Gears made of hardened steel are made to be durable, but they need to be lubricated, and plastic gears need little maintenance as well, as they have a short life.

In selecting precision gears, one should weigh the short-term against the long-term costs. Though the high-quality gears can be perceived as costly at the time of purchasing, they are more durable, efficient, and less costly in terms of maintenance in the long run. It makes them a smarter and more cost-efficient investment in the long run because investing in quality materials and accurate engineering guarantees performance ease, higher longevity, and reduced downtimes.

When considering the best quality precision gears, you should consider a brand that is concerned with precision, longevity, and high-engineering standards. The finest gears are produced with tight tolerances and high-quality materials and crafted by skilled labour in order to provide high performance under the challenging applications. Be it industrial machinery, robotics or automation, when selecting reliable, high-quality precision gears from a reputed precision gear manufacturing company, the smooth movement, reliability and eventual efficiency of the operation are certain.

The modern machinery is based on precision gears or accurate gears, which guarantee accuracy, efficiency, and reliability in innumerable applications. Every decision made influences the performance and durability, whether that decision is on the correct material to use or the ability to fit in the system with the gear. Through the cost-benefit-value and long-term benefits and advantages of investments in the high-quality and well-engineered gears, businesses may attain the benefits of smoother operations, less maintenance and increased productivity – making precision gears a good investment towards long-term mechanical perfection. Swadeshi Gears is the place to be in case you need precision gear manufacturers in India. They are a reliable supplier of any form of gears. Order now.

We are committed to delivering the highest quality services to our clients earning their trust thus ensuring complete satisfaction.

We needed ultra-small gears for a robotic automation project. The micro robotic gears from Swadeshi exceeded expectations in both performance and longevity. Great experience!

We’ve been sourcing precision and brass gears from Swadeshi for over 3 years. The consistency in quality and on-time delivery has made them our go-to supplier for automotive micro parts.

We ordered a wide range of worm wheels and spline shafts for industrial prototyping. The gear tolerance and machining precision were top-notch. Highly reliable vendor!

Swadeshi’s plastic and brass spur gears have been instrumental in scaling our production of home appliance motors. Excellent product strength and durability.

Get specialized gear manufacturing and customization services

from our experts

with every bulk inquiry

Copyright © 1996 - 2026 | Swadeshi Engineering Enterprises Pvt. Ltd. All rights reserved.

Designed & Promoted by Lead Sure Media