If you are considering investing in a spline shaft, you need to make the right choice. To do so, you can go through the following guide:

Table of Contents

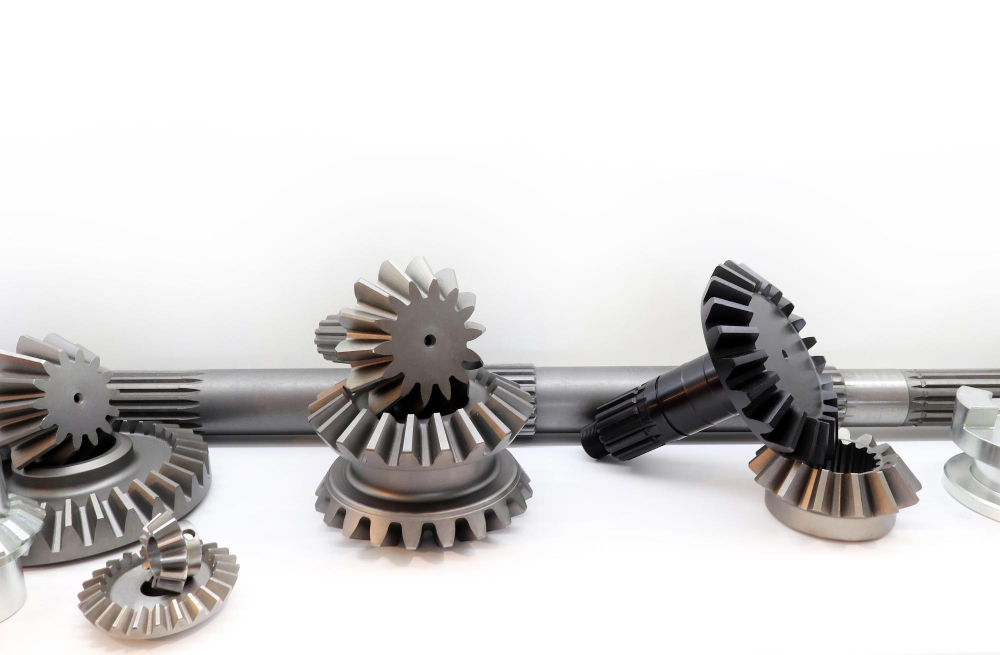

A Spline Shaft is a cylindrical shaft that is used for load distribution to maintain the machine's operation. The basic use is to transmit the torque and rotational moment between the two machines. Spline shaft uses in construction, mining, factory machines, cars, tractors, etc.

Here, power can easily be transferred without breaking the harmony of the working process.

The working of a spline shaft is simple. With the movement of the shaft, the torque is transferred through various splines. This movement allows the load to be spread evenly. The spline is designed in a way that a proper alignment between connected parts is maintained throughout the operation.

In the heavy-duty industry, spline shafts are used to transmit the torque and make sure the rotational movement between two components, such as gears and spline shaft couplings, moves smoothly. A series of elements, like ridges or teeth, is part of the outer shaft, which perfectly fits and grooves the other components.

Heavy industries like automotive, agriculture, mining, construction, etc. For having proper control and reliable power transmission, the spline shaft plays a major role in the heavy industries for load distribution and ensures the best machinery performance.

Before investing, you should consider the following table to make a better decision.

| Parameters | Description |

|---|---|

| Component Name | Spline Shaft |

| Basic Function | Transmits torque and rotational motion between connected parts |

| Shaft Type | External spline shaft |

| Spline Profile | Involute spline / Straight-sided spline |

| Material Options | Alloy steel, carbon steel, stainless steel |

| Manufacturing Process | Spline rolling, spline hobbing, spline milling |

| Surface Treatment | Heat-treated, hardened, coated |

| Load Capacity | Suitable for medium to heavy torque transmission |

| Alignment Capability | Allows axial movement while maintaining torque transfer |

| Wear Resistance | High resistance when properly heat-treated |

| Application Areas | Automotive, industrial machinery, and power transmission systems |

| Connection Type | Mates with internally splined hub or gear |

| Maintenance Requirement | Low, with proper lubrication |

| Customization Availability | Length, diameter, spline form, material |

A spline shaft requires minimal maintenance, such as proper lubrication, which will help and make sure the smooth working process.

Yes, the Spline Shaft can be customized according to demand, like the material, length, diameter, etc.

Good spline shafts are designed in such a way that they will reduce the vibration and noise.

Swadeshi Gears is the best spline shaft manufacturer in India. It has been offering high-quality gears to a plethora of industries for a long time.

Material quality, maintenance method, load conditions, and manufacturing are the reasons that affect the long service life of the spline shaft.

Here are some of the types of spline shafts:

For having a uniform torque transmission, the involute spline is mostly used as it ensures accurate alignment and high-load carrying capacity. Mostly used in automotive and industrial gearboxes.

A straight-sided spline is a simple design that is used where precise positioning is required, and load distribution is not critical. This is mostly used in agricultural machinery and construction equipment.

It can accommodate rotational and linear motion, which leads to smoother and quieter working operations. Perfectly supports the axial movement. It is mostly used in the aerospace industry and robotics.

Internal splines are used to cut inside a bore and mate with external spline shafts to transmit torque efficiently. External splines are machined on the outer surface of a shaft and engage with internally splined components.

There are different types of spline shafts, but choosing the right spline type can improve the power transmission and provide long-lasting performance.

By now, you get the basic information about what the Spline Shaft is, what its importance is, and the working process. If you are thinking of investing, then Swadeshi Gears is the best choice to purchase. With precision quality, custom build, and in-house production, which ensures solid performance.

The brand also offers small gears, small brass gears, worm gears, sector gears, and many more….

To know more, Contact Us Now.

We are committed to delivering the highest quality services to our clients earning their trust thus ensuring complete satisfaction.

We needed ultra-small gears for a robotic automation project. The micro robotic gears from Swadeshi exceeded expectations in both performance and longevity. Great experience!

We’ve been sourcing precision and brass gears from Swadeshi for over 3 years. The consistency in quality and on-time delivery has made them our go-to supplier for automotive micro parts.

We ordered a wide range of worm wheels and spline shafts for industrial prototyping. The gear tolerance and machining precision were top-notch. Highly reliable vendor!

Swadeshi’s plastic and brass spur gears have been instrumental in scaling our production of home appliance motors. Excellent product strength and durability.

Get specialized gear manufacturing and customization services

from our experts

with every bulk inquiry

Copyright © 1996 - 2026 | Swadeshi Engineering Enterprises Pvt. Ltd. All rights reserved.

Designed & Promoted by Lead Sure Media