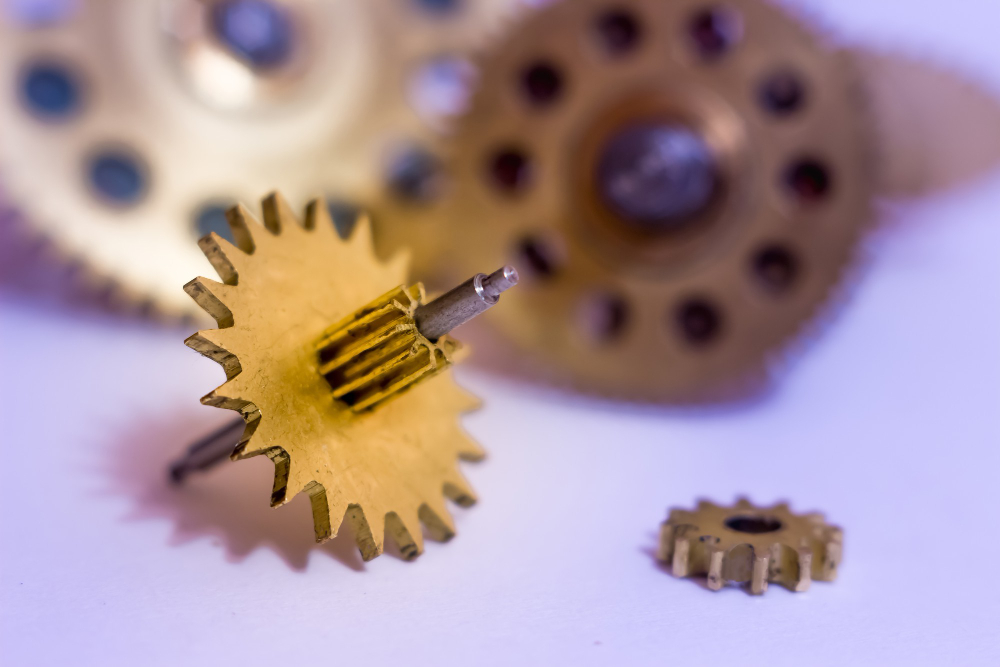

Space and precision are important in modern mechanical systems. Small gears have become the foundation of small mechanical systems, providing a smooth motion, high efficiency, and long-lasting work. Small gears are used in robotics and automation equipment, compact appliances, and precision instruments to make sure that the mechanical processes are smooth, precise, and predictable. The design enables better transfer of torque even in small spaces, and they are unavoidable in the modern high-tech machine.

The small gears and mini gear motors manufacturers are oriented toward making components that are compact and strong at the same time. These systems are not only concerned with size reduction but also with high precision as well as operation durability. Regardless of the type of small conveyor mechanism, a micro-robot, or a small actuator, the role of small gears cannot be overestimated. Small gears suppliers serve a wide range of industries, and can offer standard and or bespoke solutions to the different needs.

Small gears are not simply little imitations of the ordinary gears. Compact systems have the benefit that they offer:

When looking for Mini Gears motors, you should consider the following factors:

|

Specification |

Swadeshi Gears Product Data |

Application Insight |

|---|---|---|

|

Diameter Range |

3 mm to 50 mm |

Suitable for compact systems and micro mechanisms. |

|

Module Range |

0.15 mm to 2.0 mm (Small spur gears), 0.2 mm to 1.0 mm (micron small gears) |

Gives flexibility in torque and speed considerations. |

|

Materials Used |

Brass, Stainless Steel, Alloy Steel, Cast Iron, Mild Steel |

Offers corrosion resistance and durability. |

|

Helix Angle |

Up to 50 degrees (for small gears) |

Improves performance in precise gear arrangements. |

|

Number of Teeth |

6 to 100 (for small spur gears) |

Variety for customised gear ratios. |

Engineers who are involved in the small gears business can significantly benefit from this table.

Swadeshi Gears also focuses on the production of gears with high accuracy and strong quality control, and thus, the small gears are better in the market. Some key benefits include:

The selection of the supplier is very critical. Swadeshi Gears suppliers provide:

These aspects render them a favourite among the engineers and manufacturers who depend on miniature and high-performance mechanical systems.

Small gears are the underdogs of small mechanical systems, but they bring about accuracy, efficiency and reliability. In mini gear motors and specialised gear assemblies, quality components are vital when it comes to future performance. Swadeshi Gears integrates superior technology, professional engineering, as well as quality materials to provide customers with small gears that are superior to standard gears.

Realise the potential of today’s compact mechanical systems. Tailor-made Swadeshi Gears Incorporate Swadeshi Gears into your designs and make your models rise to a higher level by having better mini gears, small gear motors and tailor-made gears. Feel the accuracy, effectiveness and reliability in each take.

Small gears are precision mechanical components designed to transmit motion and torque in compact spaces. They are commonly used in systems where accuracy, smooth movement, and size control are important, such as instruments, automation units, and compact machines.

A smaller gear is often called a pinion. It typically meshes with a larger gear to increase torque or change speed and direction in a mechanical system.

Small gears are used to control speed, transmit motion, and manage torque in compact mechanical systems. They are essential in applications like robotics, motor assemblies, medical devices, and precision equipment where space is limited but performance is critical.

The four commonly used types of gears are:

Worm gears for high reduction ratios and compact setups

We are committed to delivering the highest quality services to our clients earning their trust thus ensuring complete satisfaction.

We needed ultra-small gears for a robotic automation project. The micro robotic gears from Swadeshi exceeded expectations in both performance and longevity. Great experience!

We’ve been sourcing precision and brass gears from Swadeshi for over 3 years. The consistency in quality and on-time delivery has made them our go-to supplier for automotive micro parts.

We ordered a wide range of worm wheels and spline shafts for industrial prototyping. The gear tolerance and machining precision were top-notch. Highly reliable vendor!

Swadeshi’s plastic and brass spur gears have been instrumental in scaling our production of home appliance motors. Excellent product strength and durability.

Get specialized gear manufacturing and customization services

from our experts

with every bulk inquiry

Copyright © 1996 - 2026 | Swadeshi Engineering Enterprises Pvt. Ltd. All rights reserved.

Designed & Promoted by Lead Sure Media